|

| Equipment of R.G.O. plant. It does not generate any substances harmful to human body such as dust, odor, and pollutants by extracting petroleum component from waste plastics. Photo= City Oil Field |

Global environment is ahead of everything in the world where we live now. Countries recognize that if they cannot secure competitiveness in the environmental sector, they cannot improve the quality of life for their people and secure national competitiveness. With this in mind, countries are competing fiercely to take the lead in the global economy by leading the environmental industry. In particular all countries are focusing on the development of technology that turns waste into resources as it can improve eco-efficiency.

Korea is in the stage of obtaining basic technologies in the clean technology and global environment sector and is far behind in terms of future-oriented environmental restoration technology and ecosystem-related basic technologies. Under this circumstances, innovative technology that turns waste plastic into energy called 'Regenerated Green Oil (R.G.O.)' technology, which has not been realized by other countries, was successfully developed by City Oil Field.

4-1. Great paradigm shift

Paradigm provides us the reason to understand the world. When a new paradigm emerges, old paradigm disappears into the history. Wherever the law of universe did change from geocentrism to heliocentrism and from Newtonian mechanics to the theory or relatively, all things in the world changed accordingly.

Although R.G.O technology is not 'Noah's Ark' that can save humans, it can save some time to make humans prepare for the upcoming disaster. In particular, paying attention to and investing in technologies that will bring about a bright future are necessary for our survival as we are likely to face disadvantages in the environmental war or lag behind in the growth as carbon neutrality is delayed.

Turning waste plastics into resources without burning or burying is a true environmental technology. R.G.O technology developed by City Oil Field is a restoration technology that will bring about a new paradigm as it meets all requirements for technology that turns waste into resources and returns waste to original resources without causing any harm.

It is proprietary technology of Korea which will improve the tarnished image of Korea (stigmatized as one of the climate villains).

4-2. Waste plastic treatment technology which will become a global standard.

Developing waste plastic treatment technology which will be a global standard is catching two birds with one stone as it is good for the environment and economy. So many (rich) countries in the world are pouring significant amount of resources unprecedently in the research in plastic recycling and re-treatment areas. It is because economic value is huge even though one of the reason is that strengthening the capability to recycle plastics is the key in the response to climate change. It will create more jobs and grow the economy.

Man countries have been looking for ways to turn petroleum-based waste (plastics, vinyl) into resources, but 'waste plastic decomposition using wave energy' developed by City Oil Field is the only technology that brings about the intended best results. City Oil Field argues that its technology will be a global standard soon. What is the reason?

4-3. How did City Oil Field find the unicorn horns?

Non-listed startups which has been younger than 10 years with corporate value of USD 1 billion (KRW 1 trillion) or over is called a unicorn company. It means that it is hard to find a non-listed startups with corporate value of more than KRW 1 trillion so that it is to find a unicorn that exists only in our imagination.

|

| Oil emulsified from waste and came out of the round window at the center of R.G.O plant. Photo= City Oil Field |

Old paradigms whether in the market or in the society, are not discarded even when the policy does not work and theory is proven to be unscientific. The new paradigm replaces the old one when an individual or minority group expels the majority which follows the old paradigm.

The process of a startup breaking up an old paradigm in the market and turning into a unicorn is like a formula.

First they can not win trust. However, they change the way the world works. They gradually form a new ecosystem. Finally, all of the technologies are added and mixed. As they are more connected and accumulated, it becomes more powerful and magical.

The R.G.O. technology developed by City Oil Gas follows this formula. Even though we cannot believe it, it does not mean that it does not exist in the world. When it is recognized, governments, institutions and companies in each country will start using it and it will change the world as it is connected with other environmental technologies.

The potential and value of R.G.O. technology developed by City Oil Field are not just a unicorn. It is more like a decacorn with more than 10 horns. Each ripple effect of R.G.O can create a huge value to the extent that it can create a unicorn. R.G.O will bring about a great global paradigm shift in the world of plastic waste treatment ultimately.

4-4. No pre-treatment and no incineration at a high temperature

|

| CEO Jeong Yeong-hoon of City Oil Field and R.G.O plant in metropolitan landfill area. Photo- City Oil Field |

Currently, the most widely used waste-to-energy methods in each country are the decomposition method through MBT and the incineration heat treatment method. MBT (Mechanical Biological Treatment) is a method of decomposing organic materials of combustible waste using aerobic microorganisms to recover energy as solid fuel (SRF). SRF is used as auxiliary fuel for power plants. Incineration heat treatment is a method of recovering thermal energy by burning waste at a high temperature. The only energy recovered in this process is heat. The heat generated during incineration is used for heating or power generation.

Both methods require pre-treatment such as screening and crushing and it is hard to install the facility in area where households are densely located as there are many risk factors. The R.G.O technology developed by City Oil Field does not require pre-treatment process unlike MBT or incineration method. Without incineration at a high temperature, it can extract high quality petroleum from the waste.

R.G.O module (plant) of City Oil Field has no chimneys. It does not generate pollutants, smoke or odor as there is no burning process so it is possible to construct the plant even in the building at the city center. It can reduce the cost of transporting waste to far away place and cost of handling carbon generation. What is the principle of turning waste plastics into petroleum without pre-treatment, burning at a high temperature and adding additives?

4-5. Turning plastics into petroleum with wave energy

R.G.O. uses photons, high-frequency and infrared waves as energy sources so pre-treatment and high temperature are not necessary. All matters have their own wave energy to maintain its existence. Therefore, all matters have molecular motion to keep their shape. If the wave is delivered from one matter to another, energy is transferred. The information contained in it is delivered. Delivering waste itself causes complex interaction of energy.

When two rhythms with the same frequency (vibration) are interact with each other and create one rhythm, it can be called interaction of wave energy. When we hang several pendulum clocks on the wall, the movement of the pendulum is delivered to the wall, creating vibration and the vibration interfere with each other, making all clocks tick in the same rhythm.

The emission of energy in the form of wave or particle is called radiation. The energy released in this way is called radiation energy. Energy delivered in the form of wave such as electromagnetic wave and gravitational wave and energy in the form of particle such as alpha and beta energy are all radiation energy. In many cases radiation energy is regarded to have the same meaning of energy of electromagnetic wave or electromagnetic wave itself. The cosmic rays which come from a distant universe is also radiation. High energy means that radiation energy is bigger than the ionization energy of molecules constituting the matter, radiation easily ionizes the electrons so that the molecules can be formed into different molecule in the end.

|

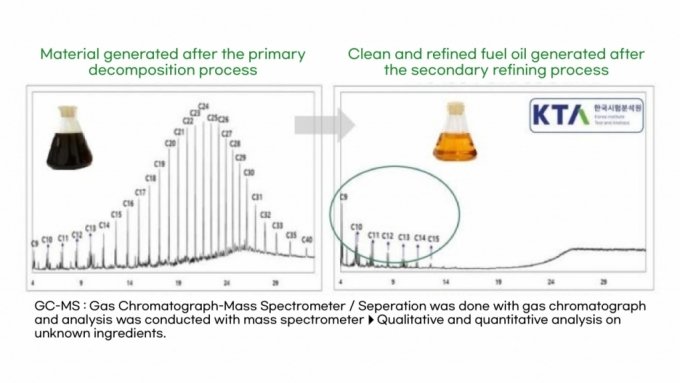

| The materials generated from the primary process composed of dozens of carbon and hydrogen rings (left) are decomposed into medium crude oil. |

4-6. Light energy breaks down carbon-hydrogen rings in the primary process

Radiation energy is also called (particle) energy of a photon. The wavelength of visible ray ranges from 400 to 700nm and this is the same region similar to binding energy of outermost electrons that are mainly involved in chemical bonding. So it is related to many chemical changes around us. For example, ultraviolet rays damage enzyme activities by changing protein in our body and breaking the molecular ring structure.

Carbons are linked together to form a long chain. When hydrogen are added to it, hydrocarbon is created. Plastics are polymers made of carbon and hydrogen. The more carbon-hydrogen rings (thousands, tens of thousands), the harder the polymer and the less (dozens) the rings, the more liquid form of petroleum. If the number of carbons is 4 or less it becomes gas and from 5 to dozens it will become liquid. If the number of carbons is higher than dozens it will become solid. Methane used as city gas has only one carbon, and if there are 3 to 4 carbons it becomes liquefied petroleum gas. If 5 to 10 carbons exist, gasoline is made. If the number is 11 to 15 kerosene is made and if it is 15 to 20 diesel oil is made. Bunker oil has 20 to 40 carbons.

R.G.O. uses photons, high frequency and UV-C(ultraviolet ray ranging from 100 to 280nm) wave energy. The wave energy coming from a ceramic ball that emits three types of wave length respectively cracks down LDPE with thousands or tens of thousands carbon-hydrogen rings into a matter with dozens of carbon-hydrogen ring (naphtha). It is to turn the plastic into original material. When gaseous hydrocarbons extracted in the primary process in the plant are liquefied, they become heavy oil (bunker oil). This heavy oil goes through a secondary process to produce diesel that can be used as fuel for industry.

4-7. Difference from Japan's pyrolysis emulsion technology

The pyrolysis emulsification technology is a method of producing liquid fuel (petroleum) by sorting waste plastics by type and heating them at a temperature of 350~650°C through pretreatment processes such as washing and crushing. Kankyo-energy and Recycle-energy are the Japanese companies that have the world's best pyrolysis emulsification technology so far.

'HiCOP-200' developed by Kankyo-energy for waste plastic emulsification adopts a cracking method based on catalyst and is said to be capable of high-quality emulsification that cannot be achieved with conventional pyrolysis technology. SKC, a Korean company, signed a memorandum of understanding with Kankyo-energy on June 8 for cooperation on the commercialization of pyrolysis technology for waste plastics. SKC plans to produce more than 35,000 tons of pyrolysis oil by injecting more than 50,000 tons of plastic waste with the goal of commercial operation in 2023 by securing joint ownership of technology and exclusive license for Kankyo-energy.

Recycle-energy under the CFP group, possesses a patented technology that can manufacturer oil that does not solidify even at low temperature under 0℃. It resolves the problem of oil solidification at a low temperature in winter time when existing pyrolysis technology is applied. If there is 2 units of emulsification units with capacity of 4,000kg/day(400kg/h), it is possible to produce 8,000 liters of oil from 8,000 kg of waste plastic a day.

Korea has been developing pyrolysis since mid 2000, it failed to commercialize the technology due to lack of dichlorination technology. Japan successfully commercialize the technology through active R&D investment but it is not establishing supply chain as it faces high barrier of the cost of environmental pollution reduction facilities such as pretreatment and dichlorination facilities.

Japanese emulsification companies pay attention to City Oil Field plant as it considers that if the plant can process mixed multi-layer resin (ramen package that includes metal foil) and other waste together, it will be very advantageous to enter the Chinese market. In turn, it does not believe the emulsification without pretreatment but believe that if it is possible, it will become a dominant technology in the market. It is said that discussion is underway with China as Chinese companies ask the possibility of manufacturing low-temperature (400℃) emulsification plant where it can apply minimum pre-treatment and charge the waste.

* In part 3, articles under the theme of <Waste to Resource Technology, an Invisible Light in the 4th Industrial Revolution> will follow.

![돌연 사라진 70대 재력가…내연녀 집 시멘트 부쉈더니 시신으로[뉴스속오늘]](https://thumb.mt.co.kr/11/2024/04/2024042417433499310_1.jpg/dims/resize/100x/optimize/)

![테슬라 압박하는 단 한 가지 문제…다음주 머스크가 답해야[오미주]](https://thumb.mt.co.kr/11/2024/04/2024041914093324262_1.jpg/dims/resize/100x/optimize/)

!["8000원짜리 알리선 2000원"…중국 '직구' 외면할 수 있을까?[차이나는 중국]](https://thumb.mt.co.kr/11/2024/04/2024041817512119098_1.jpg/dims/resize/100x/optimize/)

![모리스 창이 55세에 TSMC를 창업해 성공시킨 비결 [PADO]](https://thumb.mt.co.kr/11/2024/04/2024041914180910132_1.jpg/dims/resize/100x/optimize/)

!["꼭 가야 해" 사람 가득 실은 배 30분 만에 침몰…292명 대참사[뉴스속오늘]](https://thumb.mt.co.kr/10/2023/10/2023100611053583558_1.jpg/dims/resize/100x/optimize)

![미국 대선, 6개주만 보면 답 나온다 [PADO 편집장의 '미국 대 미국']](https://i4.ytimg.com/vi/7kc1ddGnWtE/hqdefault.jpg)